Seal Test / Sealing Test services|seal testing techniques pdf : traders Our materials specialists are able to perform a range of testing services to . The Complete Pornstar list on TW Pornstars. 1 #1 Black PO.

{plog:ftitle_list}

XNXX HINDI XNXX indo porn European Porn. Sex Video,Sex Porno,Seks Porno,XXX 1080p Video,ankha XXX,YouPorn,XVIDEOS,jav hd,erotic film. XNXX Porn Movies,XNXX.COM .

Hallite seals integrity testing include but aren't limited to friction and leakage test, speed, temperature, and pressure testing. Contact us today!Whether in-house testing or field trials, we are able to reproduce ideal and worst .

Our materials specialists are able to perform a range of testing services to .Our materials specialists are able to perform a range of testing services to .Whether in-house testing or field trials, we are able to reproduce ideal and worst .

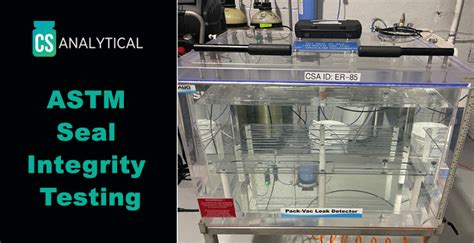

The answer lies in seal strength testing—a critical process in quality control for packaged goods. Seal strength test methods evaluate the integrity of seals on various types of packaging, from food containers to medical supplies. . The duration of the sealing process significantly affects seal strength: Sealing time must be sufficient to .Various criteria such as the force required and the chamfering of the sealed seam are evaluated. Alongside the seal check, the ink test and the seal seam strength test, the peel test is a common method for assessing the seal seam quality of a sealing device. Performing the peel test makes it possible to detect and rectify faulty seals in good time.characteristic of the package. There are two basic types of seal strength testing addressed in ISO-11607: tensile strength testing and burst or creep (inflation) testing. Tensile seal strength testing (ASTM F88) uses a defined width sample (25.4mm) of the package seal perimeter. A jaw moving at a defined constant rate 10 to 12 in/min. pullsHeat seal test is to determine the suitable sealing parameters (sealing temperature, dwell time and pressure) for materials. Complies with ASTM F2029 - Standard Practices for Making Heatseals for Determination of Heatsealability of Flexible s as Measured by Seal Strength

For validation of hydraulic sealing systems, we provide test rigs that enables customer-specific tests as lifetime tests for hydraulic and pneumatic sealing systems in combination with lubricants. Next to friction and assembly tests, high- and low-temperature tests to identify the best component for individual processes.Residual Seal Force (RSF) is an evaluation of the quality of this seal. The glass vials subjected to RSF evaluation are used exclusively within the healthcare industry. A perfect example of the importance of RSF testing is the COVID-19 vaccine: some of the vaccines need to be stored at extremely cold temperatures in order to remain effective.

Seal Test, Fine & Gross Leak. The purpose of the seal test is to determine the effectiveness of the sealing of components with internal cavities, i.e. to determine their hermeticity. Defective sealing may permit the entrance of contaminants, thus reducing the effective life and reliability of devices. John McLaughlin is manager of product testing for Trelleborg Sealing Solutions. He has more than 15 years of experience in product testing of polymer base products. . During those years, he has had the opportunity to manage and/or play a key role in seal and bearing testing, test method development, final validation, defining root case .CO2 transmission rate test by weighing method: Water vapor transmission rate test by inverted cup method: Non-destructive test for packaging seal performance: Multi-station packaging pressure test: Tensile test of packaging materials with ultra-long elongation: Heat-seal strength test for cap films of medical bottles, yogurt cups and jelly cups

The test procedure may be used to test seals of alternate size and design or using alternative media but such deviations shall be detailed separately on the report form and the results shall not be used to determine the minimum operating temperature of seals .The Sepha PakScan is a non-destructive test method. The machine performs a dry seal integrity test enabling manufactures to recover packs that have passed the leak test and return them to the production line. The system can identify gross holes, leaks and weak seals down to 10μm* in up to 10 packs simultaneously within 30 seconds.

Testing Methods: ISO 11607 specifies various testing methods for assessing seal strength, including peel testing, burst testing, and leakage testing. These methods help in evaluating the performance of packaging systems under different conditions and ensuring their suitability for medical device applications.Seal tests ISO11607-2 (Validation requirements for forming, sealing and assembly processes), requires Operational Qualification (OQ) of packaging devices to be carried out and documented. The OQ is requiring providing proof of: Intact seal for a specific seal width No channels or open seals No punctures or tears in seals No material delaminating or separation The OQ needs to The easiest to do is hot water seal. Use distilled or demineralised water with a conductivity below 150 microsiemens and a pH of about 6 (5.5-6.5 is not uncommon). Seal for 10-30 minutes at 96 °C minimum, preferably boiling. Dichromate seal can be done in anything from a ppm solution of sodium or potassium dichromate up to a 10% solution.

seal testing techniques pdf

The seal strength test employs a universal testing machine with its jaw separation rate set between 200 to 300 mm/min (8 to 12 in/min). The test procedure is as follows: Use a sample cutter to cut a one-inch wide strip in the seal on each of the four sides of the pouch or package.Duct sealing and duct leakage testing: Two experts from Conservation Services Group, Eric Wilder and Will D’Arrigo, explain how to seal duct seams with mastic and how to use a Duct Blaster to test duct tightness . Energy 13 conference in Boston on March 6, 2013, duct sealing experts Eric Wilder and Will D’Arrigo explain how to seal leaks .

watering cannabis with moisture meter

Why would you need to air seal your home? Every house needs healthy airflow. Natural airflow helps prevent the buildup of mold and mildew throughout your house, and mechanical airflow (like the vent from your furnace) prevents .Stein Seal ® Company developed dynamic test rig capable of simulating extreme engine attitudes at any angle ranging from horizontal up to 90⁰ vertical in order to verify seal performance. In addition to matching gas turbine engine bearing sump pressures and temperatures, the rig shaft rotates at speeds up to 20,000 rpm and can be maintained .

Dr. Energy Saver provides complete air leakage testing and air sealing services. Call today for an estimate! 1-866-632-5870 Request A Free Estimate. 1-866-632-5870 . When you air seal your home, you will notice enhanced air quality, less humidity, and increased comfortability. Plus, your home will no longer require a large amount of energy to .Seal Testing Services. Ensuring the integrity and functionality of your seals is crucial for operational success. Our comprehensive seal testing services are designed to evaluate and validate the performance of your sealing solutions. We employ a range of rigorous testing methods to simulate real-world conditions, identifying potential issues .sealing cycle but prior to the temperature of the seal reaching ambient. Refer to Test Methods F1921. 3.1.6 seal initiation temperature, n—on a heat seal curve, the sealing temperature/dwell pressure at which heat seal strength first begins to trend upward from zero heat seal strength. 3.1.7 sealing interface, n—the interface of the two webSeal strength testing evaluates the mechanical strength of the seal, assuring proper bonding and providing an indicator of package integrity throughout the life of the package for a variety of pouch package systems holding drug product or medical devices. . Advisory Services; 1-888-571-1207. . These test methods fall under the general .

If your house qualifies, you might be able to get a complete home air sealing package (including duct sealing and insulation upgrades) for ZERO money upfront. Get whole-house air and duct sealing—for NO upfront cost. Yes, really. Here’s our 10-second spiel for how it works.Heat Seal Testing Sentinel Heat Sealer. Heat sealing has a number of different packaging applications. The Sentinel Heat Sealer has two independently heated platens and can test a variety of nip pressures and dwell times. We generally test paperboard materials and determine the degree of heat sealability by measuring the percent fiber tear from .Sealing methods for leak testing Sealing technology is very important to reliably performing leak tests. Here, we list some topics related to actual sealing methods and sealing technology.1.Sealing gaskets. Gasket seals; O-ring seals; Recommended design for O-ring grooves; Sealing WORKs with large openings; 2. Clamp mechanisms. Tooling stoppersonly the maximum hot seal strength achievable by each material and the sealing temperature required, but also the breadth of the sealing temperature range at any specified level of hot tack. 3.1.11 sealing temperature, n—maximum temperature reached at the interface between the two web surfaces being sealed, during the dwell time of the .

Air-sealing Strategies: As Easy as ABC. With the visual inspection and blower door test complete, you should have a pretty good idea of your how much impact leaks are having on your energy use and comfort. The next question is to figure out where to start. This diagram illustrates how we eliminate air leaks in the home (click to enlarge).

seal testing techniques

seal testing methods pdf

New 18+ UK customers only. Register using the promo code .

Seal Test / Sealing Test services|seal testing techniques pdf